Vapour Phase Oven Price

3l becher pyrex heater cheap chinese like and an optional thermocouple reader.

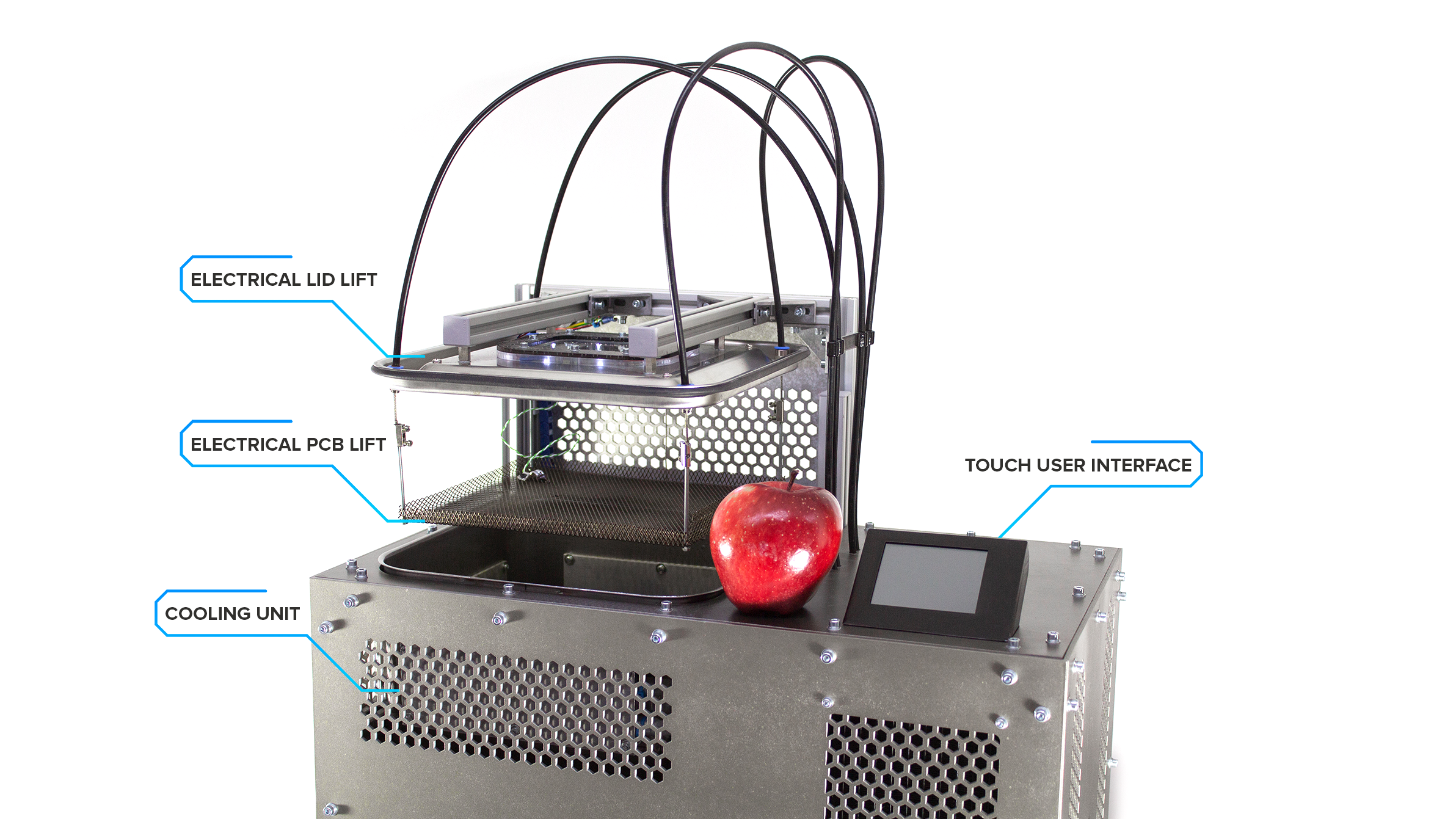

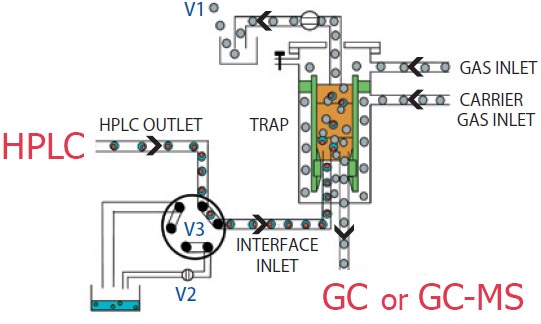

Vapour phase oven price. The liquid used is chosen with a desired boiling point in mind to suit the solder alloy to be reflowed. This allows the soldered parts to remain sealed inside a neutral atmosphere. The heating of the pcbs is sourced by thermal energy emitted by the phase transition of a heat transfer liquid e. There are generally two types of systems depending on the process used.

A 230 c boiling fluid g. Smd vapour phase reflow soldering process. For instance the inert fluid boils at 230 c and creates the. The vapor phase process is the ideal solution to reflow temperature control issues in small batch production runs.

Browse related vapor vapor phase oven vapor degreaser vapor oven some facts about us 1. Contact us for a quote. With vapour phase soldering the pcb is submerged in hot galden vapour. Hering offers the right equipment for every application in order to ensure an optimal price performance ratio.

The vapour phase process involve heating up the pcb through the galden vapour an inert medium. Unlike ir or convection batch type ovens with varying temperature control concerns our vapor phase ovens provide you with evenly distributed temperature throughout the production cycle completely under your control. Reflow soldering of smd pcbas may appear simple as all you need to do is apply heat to melt the solder paste but. Vapour phase is considered to have process advantages over convection in terms of giving control and stability over the reflow cycle.

Ibl minilab vapour phase batch soldering oven ideal for development prototyping rework and miniseries production board sizes up to 300 x 275 x 80 mm table top unit. This is an starting price for the machine without accessories. Simple made home made vapor phase oven. Hot air drying plant easy setup.

This vapour transfers heat to the pcb and melts the solder. As the vapor has a higher density it is heavier than the surrounding air. 100 mva vapor phase drying plant reduced process duration. Vapour phase offers a better consistency in quality than small reflow ovens.

Pfpe condensing on the pcbs. Vapour phase is an alternative to ir reflow ovens.