Trash Rack Cleaning Machine Design

The trcs is already setting 1200 tons of trash rack panels.

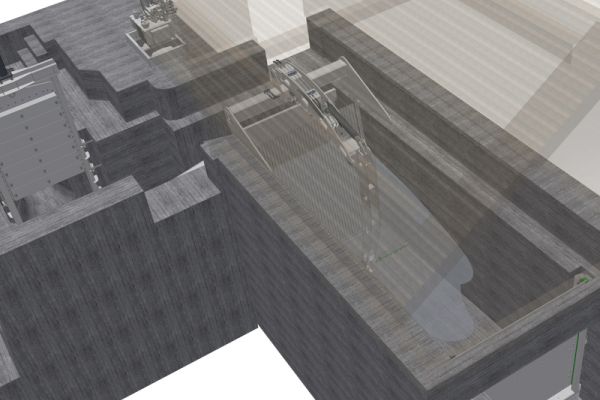

Trash rack cleaning machine design. Hydraulic trash rack cleaning thanks to their flexibility and robust design our hydraulic systems are perfectly suited to remove bulky debris from vertical and inclined trash racks. Manual or fully automatic operation. Trash rack cleaning machine 1 scope the work includes the design manufacturing supply transportation handling storage installation including 1st and 2nd stage embedded parts and any other necessary element for the proper operation testing and commissioning of the trash rack cleaning machine with all mechanical electrical control and. Mecos hydro builds chain driven hydraulic chassis hydraulic and rotating trash rack cleaning machines.

This specially designed machine is equipped with a 12 3m wide cleaning rake and is expected to clean 14 intakes. The trash bars run from top to bottom and are supported by lateral bars. The trash rack cleaning and the removal of the debris are implemented in a single process step. Enjoy the videos and music you love upload original content and share it all with friends family and the world on youtube.

In particular in the autumn when leaves fall from the trees or in the winter when ice covers some parts cleaning machines can guarantee an increase in capacity of up to 30. Trash rack cleaning machine are intended to remove trashes debris logs plants etc accumulated at the intake trash racks for hydel and thermal power plants and other water management utilities the machines are available according to the plant design and customers requirement. Trash rack cleaning machines depending on the scope of contamination trash rack cleaning machines secure high energy use of your hydropower station. State of the art control technology enables automatic operation with the highest degree of safety.

Hand held rake to a sophisticated automated mechanical cleaning machine. Each one of these models has been designed for the removal by special rakes of detritus and solid waste that accumulate against the screens installed for protection. Automated surface debris removal. The type of cleaning device selected should depend on the particular needs at the site.

Due to the curved dam construction the machine has to travel on a curved rail system. Design standards assists in the development and improvement of reclamation facilities in a way.